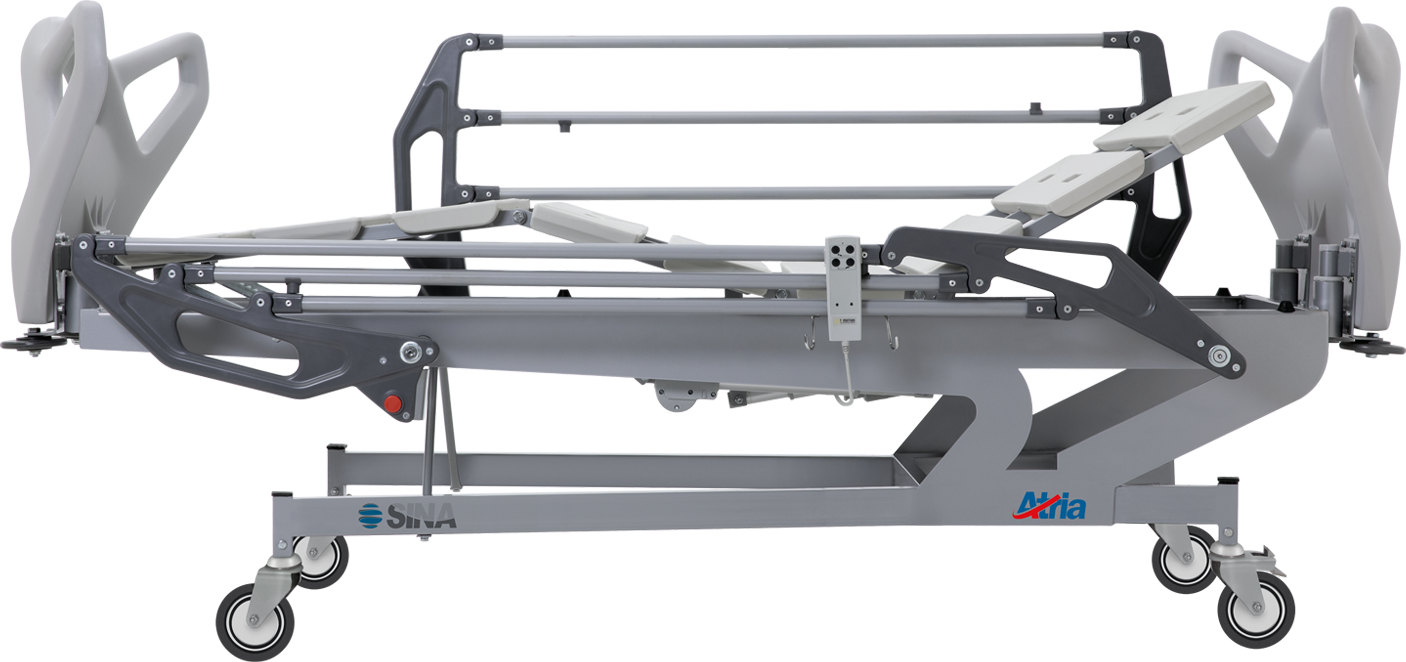

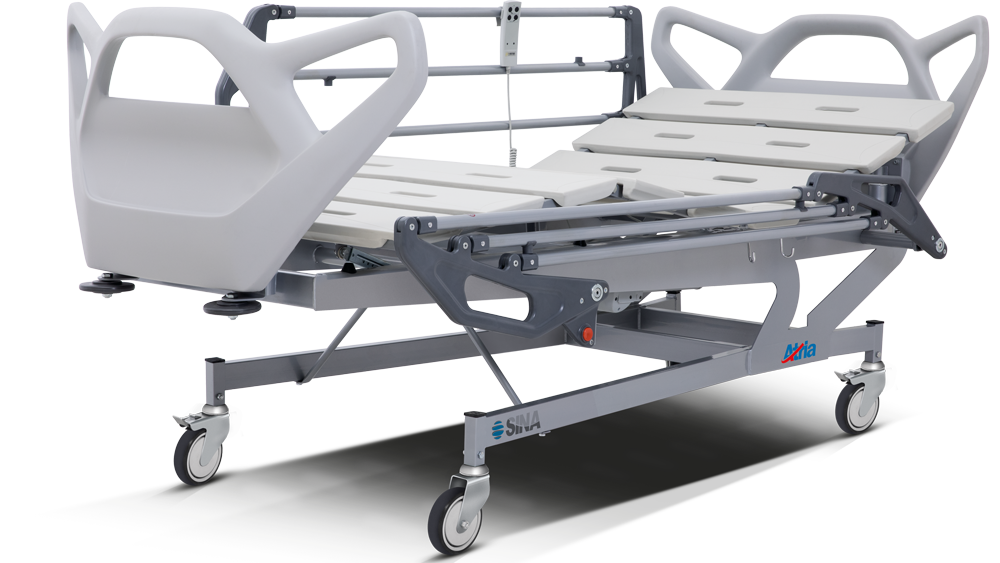

Our product design focuses on key needs, ensuring a cost-effective and user-friendly product. Atria, a hospital bed with a unique design as the strength of this product, has always been the focus of users and customers.

Atria series beds

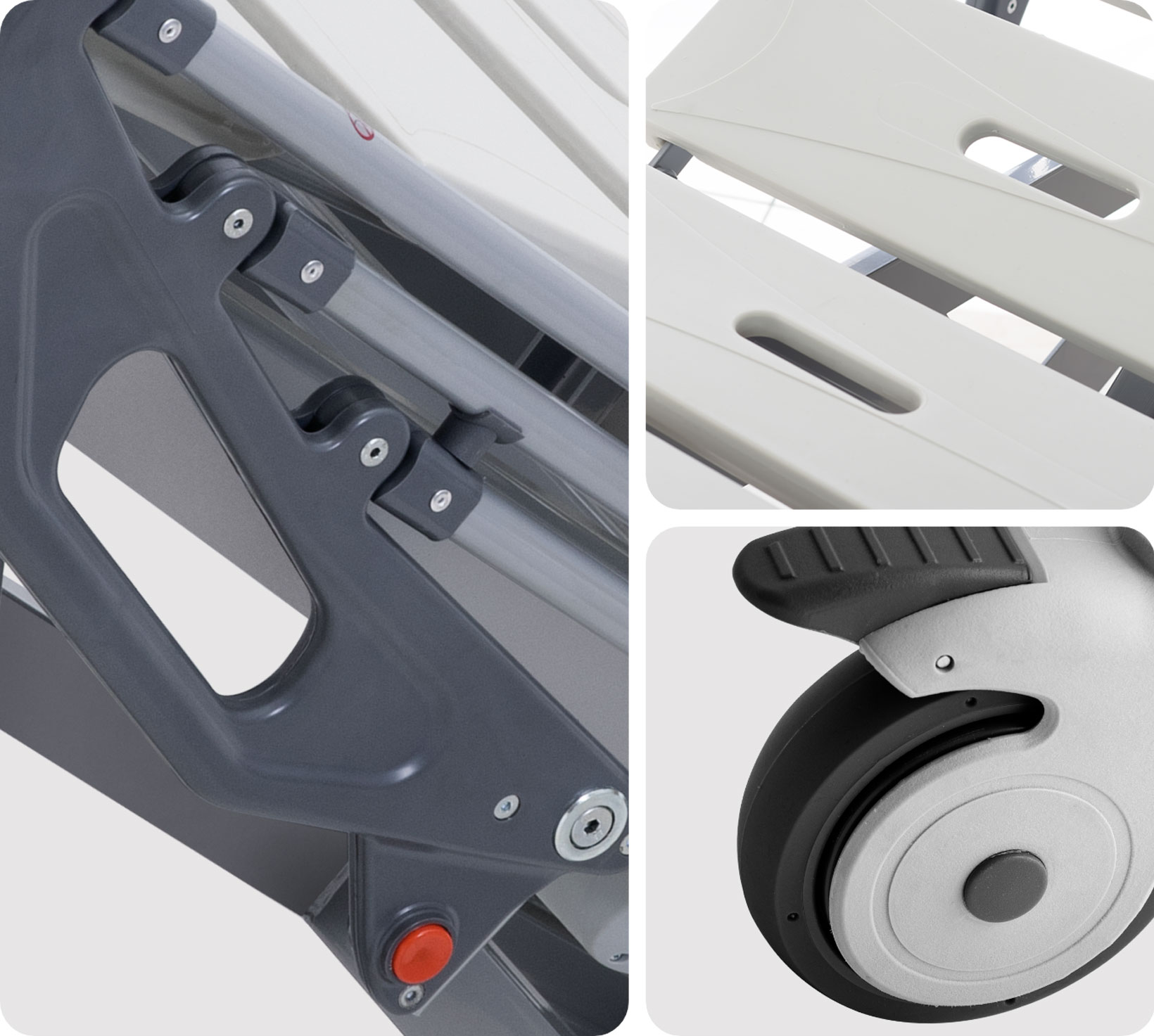

The material used to produce the flat bed with a special two-layer design has created a very smooth surface for easy cleaning and disinfection. The high weight bearing capacity, the possibility of air flow and being unbreakable can be considered as the advantages of this product.

- Mattress platform is four section, three of them adjustable. Covered with integrated plastic Two - ply surface

- Airflow capability under the mattress

- Backrest, knee raise and Hi - Low adjustments are electrically

- Foot section is adjustable by means of telescopic bracket

- Plastofold collapsible siderails with metal chassis inside

- It has a resistant P.P. sideboard joint

- Three-functional positioning wired handset

- Detachable head and foot boards with metal connection and suitable ergonomic style for easy handling

- Washable and disinfectable

- CPR handle on both sides for flattening backrest rapidly

- Electrostatic powder coating

- Four rubber bumpers at corners

- IV stand holder at each corner

- Traction holder

- Urine bag holder at both side

Mattress platform 2000 x 900 (mm)

Bed net weight 110 Kg

Safe working load capacity 170 Kg

Castors 125 (mm) diameter

Backrest angle 0º - 80º

Overall 2330 x 1030 (mm)

For the Beauty of Hospitals

For the Beauty of Hospitals

Although thick sheets and profiles are used in the construction of Atria At the same time, the movement threshold is lower than the international standards due to the use of high-quality mobile wheels

The use of double-layer inflatable insoles made of polyethylene makes you feel at ease about breaking and rotting and gives you the possibility of easy washing and disinfection in the long term.

Smooth Surface for

Smooth Surface for Easy to clean and disinfect

-

تخت احیاء بیمار سه شکن مکانيکي مدل A431OO51 - تخت CPR

تخت احیاء بیمار یا تخت CPR یک تجهیز حیاتی است که در محیطهای پزشکی برای ارائه بهترین مراقبت در مواجهه با حالات اورژانسی ناگهانی، به خصوص در مواقع ایست قلبی ...

-

برانکارد اطفال مدل Stra4143.3

جابه جایی بیمار اطفال نه تنها برای خود بیمار اطفال بلکه برای پرستاران نیز مهم و تاثیر گذار است. در سینا ما بر این باور هستیم اقدامات اولیه در مواجهه ...

-

تخت اطفال الکتریکی ویژه B4021PROO PICU

چهارتکه، سه شکن با رویه پلاستیکی کاملا مستحکم با شاسی تقویتی دارای قابلیت رادیوگرافی رنگ پودری الکترواستاتیک دارای سایدریلهای lever ارگونومی شده جهت باز و بست سریع و آسان دارای ...

-

تخت احیای نوزاد مدل Lyona I2101WPRO

تخت احیای نوزاد یک تجهیز پزشکی است که برای ارائه مراقبتهای اولیه به نوزادان تازه متولد شده که نیاز به حمایت تنفسی و قلبی دارند، استفاده میشود. این تخت به ...

-

Pedia B0060.2

A children's bed with strong and strengthened chassis can be the best option for shopping. Sina's children's children are equipped with a pedal system lock that 2 ...

-

M24.1

The examination bed is used as a patient examination bed in medical centers. Patient examination mattress with two fixed pieces and a breaker designed and offered ...

-

The base of the five -plastic serum with the wheel

Serum base is one of the essential equipment in medical centers that helps patients and physicians.

-

Single steps next to the patient's bed m23

Staircase next to the patient's bed is one of the essential and common medical equipment used in a variety of medical centers and hospitals. These stairs are different sex and shape ...

-

4 -metal serum base

Serum base is one of the essential equipment in medical centers that helps patients and physicians.

-

Paravan

Paravan is a separate hospital used in all therapeutic areas such as clinics, offices, hospitals. Paravans ...

-

Castia DT3101POOE

The new delivery bed designed in the Sina Design Unit provides the comfort of the mother and the nurse during childbirth with functional features. Accessories and Options ...

-

Asa R6120

ASA R6120 foldable patient bed is made from the best raw materials available in the market so that you can use it easily and with peace of mind. Material of seat and arm...

-

Pedia B0050.1:2018

A children's bed with two pieces of 1.5 mm metal bottom with reinforced and strong chassis can be the best option to buy. Sina children's bed wheels...

-

SCALA T4301PRC

Scala series beds are used in intensive care units. The system of these beds is easy to use in order to meet the needs of nurses and patients and create a sense of security and comfort for patients...

-

Stra 4143.1

Moving the patient is important and effective not only for the patient but also for the nurses. In Sina, we believe that the first steps in direct confrontation with...

-

Stra 4243

Moving the patient is important and effective not only for the patient but also for the nurses. In Sina, we believe that the first steps in direct confrontation with...

-

M52.5

The plastic footboard is made of ABS plastic, which can be easily used and disinfected. This four plastic four plastic double bed wardrobe...

-

SCALA T4401PROO.1

Scala series beds are used in intensive care units. The system of these beds is easy to use in order to meet the needs of nurses and patients and create a sense of security and comfort for patients...

-

SCALA T2101POOO

Scala series beds are used in intensive care units. The system of these beds is easy to use in order to meet the needs of nurses and patients and create a sense of security and comfort for patients...

-

SCALA T4301PRO

Scala series beds are used in intensive care units. The system of these beds is easy to use in order to meet the needs of nurses and patients and create a sense of security and comfort for patients...

-

OBT 02

The OBT 02 model hospital dining table is produced in Sina Hamdaria company, which is made of ABS plastic that can be washed and disinfected. bases ...

-

Lyona l2100WPRO

Newborn babies usually cannot regulate their body temperature and therefore need help to maintain their body temperature to desired levels ...

-

ATRIA A311PO21.1

Our product design focuses on key needs, ensuring a cost-effective and user-friendly product. Atria is a hospital bed with a unique design as...

-

ATRIA MT1.2

Our product design focuses on key needs, ensuring a cost-effective and user-friendly product. Atria is a hospital bed with a unique design as...

-

Stra S1200

Moving the patient is important and effective not only for the patient but also for the nurses. In Sina, we believe that the first steps in direct confrontation with...

-

Stra S4100.1

Moving the patient is important and effective not only for the patient but also for the nurses. In Sina, we believe that the first steps in direct confrontation with...

-

SCALA T4001PROO

Scala series beds are used in intensive care units. The system of these beds is easy to use in order to meet the needs of nurses and patients and create a sense of security and comfort for patients...

-

ATRIA A412PO21

Our product design focuses on key needs, ensuring a cost-effective and user-friendly product. Atria is a hospital bed with a unique design as...

-

SCALA T4401PROO.2

Scala series beds are used in intensive care units. The system of these beds is easy to use in order to meet the needs of nurses and patients and create a sense of security and comfort for patients...

-

Pedia B0060

A children's bed with two pieces of 4 mm metal bottom with reinforced and strong chassis can be the best option to buy. Sina children's bed wheels...

-

SMI6000

SMI6000 foldable patient bed is made from the best raw materials available in the market so that you can use it easily and with peace of mind. Material of seat and arm...

-

M24.1

تخت معاینه یک شکن مدل M24.1 به عنوان تخت معاینه بیمار در مراکز درمانی مورد استفاده قرار می گیرد. تشک تخت معاینه بیمار مدل M24.1 2 با دو تکه ثابت ...

-

BDC2111211

با خرید صندلی خونگیری آزمایشگاهی دو شکن مدل BDC2111211 از شرکت سینا حمدآریا (اولین و بزرگترین تولیدی صندلی و تخت بیمارستانی) دیگر نیازی روش های سنتی برای خونگیری ندارید. قیمت ...

-

R1111FA

تخت روانپزشکی یک شکن مدل R1111FA برای بیمارانی طراحی شده است که دارای اختلالات عصبی و بیمار های روانشناسی می باشد. تخت روانپزشکی طوری طراحی شده است که تا حد ...

-

M20000010.9010

تشک بیمارستان جهت نگهداشت بیمار بروی بستر تخت های بیمارستانی برای کمک در روند معالجه و استراحت بیمار طراحی و تولید گردیده است. وزن کل تشک 6 کیلوگرم می باشد ...

-

OBT 05

میز غذای بیمارستانی مدل OBT 05 تولید شده در شرکت سینا حمدآریا می باشد که از رویه پلاستیکی ABS می باشد که قابلیت شستشو و ضدعفونی را دارد. پایه های ...

-

ATRIA ET1

Our product design focuses on key needs, ensuring a cost-effective and user-friendly product. Atria is a hospital bed with a unique design as...

-

ATRIA L3000POO

Our product design focuses on key needs, ensuring a cost-effective and user-friendly product. Atria is a hospital bed with a unique design as...

-

Hospina H3140

تختهای سری هاسپینا، شامل تختهایی می باشد که عمدتاً در بخشهای دیالیز و پلاسما کاربرد دارند. تختهای هاسپینا به پرستاران کمک می کند تا بهترین مراقبت را از بیماران داشته ...

-

Castia DT3101POCE1.2

The new delivery bed designed in the Sina Design Unit provides the comfort of the mother and the nurse during childbirth with functional features. Accessories and Options ...

تخت های بستری بیمار سری آتریا

سری آتریا شامل تخت های سه شکن بستری مکانیکی و الکتریکی بوده و قابل استفاده در بخش های مختلف بیمارستانی می باشد .این گروه بصورت Bed with three electric motors که دارای سه الکترو موتور که برای تنظیم ارتفاع ،تنظیم بک رست و تنظیم زانو مورد استفاده قرار میگیرد برای تغییر پوزیشن یک عدد هندست دستی لحاظ شده است .

کارشناسان سینا بازخوردها و انتقادات کاربران و همچنین تجربیات انباشته چندین ساله کارشناسان خدمات پس از فروش ،بررسی های دوره ای و استانداردهای جهانی در طراحی و ساخت قطعات اتریا مورد توجه قرار داده و بالاخره در کارخانه سینا پس از تست های مختلف از جمله تست بار کامل در آزمایشگاه کنترل کیفی کارخانه ،به مرحله تولید رسانده اند .

Hospital bed Atria series دارای ساید بورد جهت حفظ امنیت بیمار میباشد. تخت های دو موتوره الکتریکی که دارای دو موتور برای تنظیم بک رست و زانو مورد استفاده قرار میگیرد و هندست دستی جهت پوزیشن گیری مورد استفاده قرار میگیرد .

توجه ویژه به زیبایی در سری آتریا

یکی دیگر از تخت های گروه آتریا تخت بستری مکانیکی سه شکن می باشد که پوزیشن بکرست و زانو توسط جک های مکانیکی هرزگرد پوزیشن می گیرد در این گروه نیز یک جفت بدساید در طرفین تخت جهت حفظ امنیت بیمار لحاظ شده است. Special mechanical bed که در بخش های ویژه بیمارستان مورد استفاده قرار میگیرد سه شکن بوده و پوزیشن ترند و ریورس ترند نیز توسط جک مکانیکال هرزگرد احراز می شود در این تخت ساید برد های استفاده شده چهار تیکه پلاستیکی می باشد .

عمده ترین مشکلاتی که مراکز درمانی با تخت های بستری مواجه هستند شکستگی کفه های تخت های بیمارستانی و مورد دوم شکستگی سر تخت ها و مورد سوم خرابی جک های بالا برنده و در نهایت مفاصل بدساید ها که عمدتا میشکنند ،می باشد ما در این گروه از تخت ها از کفه های بادی نشکن استفاده کردیم .

در قسمت بالابرنده تخت ها برای افزایش عمر مفید تخت ها از سیستم هرزگرد شده است و در قسمت سر تخت ها از سر تخت های پلاستیکی با پایه فلزی جهت حفظ استحکام استفاده کرده ایم. چرخ های این سری تخت های شرکت سینا حمدآریا از جنس پلی اورتان بوده و تولید شرکت دراج حمدآریا می باشد که بدون کوچیک ترین آسیب دیدگی یا تغییر شکل می توان آن ها را ساعت ها روی آسفالت حرکت دهید .

این گروه از تخت ها در شرکت سینا حمدآریا با بیش از ۵۰ سال سابقه، تولید و در بازار عرضه میگردد به طوری که سالانه هزاران تخت به سراسر دنیا عرضه می شود.

)